Description of the Port

Puerto Cortés is the main Honduran port and one of the most important on the Atlantic slope of Central America, handling 86% of the total containers moved annually by the port (in 2013 the movement of 571,000 TEUS was reported, in 2014 it increased to 582,000, in 2015 it shot up to 628,000, in 2016 it rose to 634,000 and in 2017 it increased to 655,000 TEUS) and 77% in metric tons (MT) of general cargo, special (such as bananas, coffee, melons, pineapples and other fruits for which it has adequate equipment to maintain the cold chain) and solid bulks in specialized and multipurpose docks. It has two active concessionaires: Operadora Portuaria Centroamericana (container and general cargo terminal) and Terminal Especializada de Honduras (solid bulk).

The port's productivity has risen from 19 movements per hour per vessel in 2014 to more than 50 in 2022. The acquisition of 2 Super Post Panamax gantry cranes has been contributing to improving the efficiency of Puerto Cortés. There have also been savings in truck service time, reducing from 63 minutes when the terminal was received to 40 minutes.

During 2022, shipments of ready-made clothing, bananas, coffee and prepared groceries stood out, and the main import products have been cotton yarn, varied merchandise, used vehicles and construction materials. It should be noted that the terminal has had the largest movement of cars in its history during 2022, exceeding 2,000 to date. In the month of August 2022 alone, more than 1,200 were received and the trend is expected to continue to be positive.

Port website: https://www.enp.hn/

You can also find information about key ports at: http://www.maritime-database.com

|

Port Location and Contact |

|

|---|---|

|

Country |

Honduras |

|

Province or District |

Cortes |

|

Nearest Town or City with Distance from Port |

Omoa 13.2 km |

|

Full port name |

Puerto Cortes |

|

Latitude |

15°48"00 North latitude |

|

Longitude |

87°57"00 West longitude |

|

Management Company or Port Authority |

Port Authority: National Port Company Solid Bulk Terminal: Grupo LOGRA, TEH (Specialized Terminals of Honduras), AVANZA General Cargo and Containers: ICTS (International Container Terminal Services, Inc) through OPC (Operadora Portuaria Centroamericana) |

|

Management Level Contact Person |

Jose Manuel Mencia |

|

Nearest airports with frequent international arrivals/departures |

Ramón Villeda Morales International Airport (Avianca, Aero Mexico, American Airlines, Air Europa, Copa Airlines, Delta, Spirit, United Airlines, Volaris) |

Photos of the Port

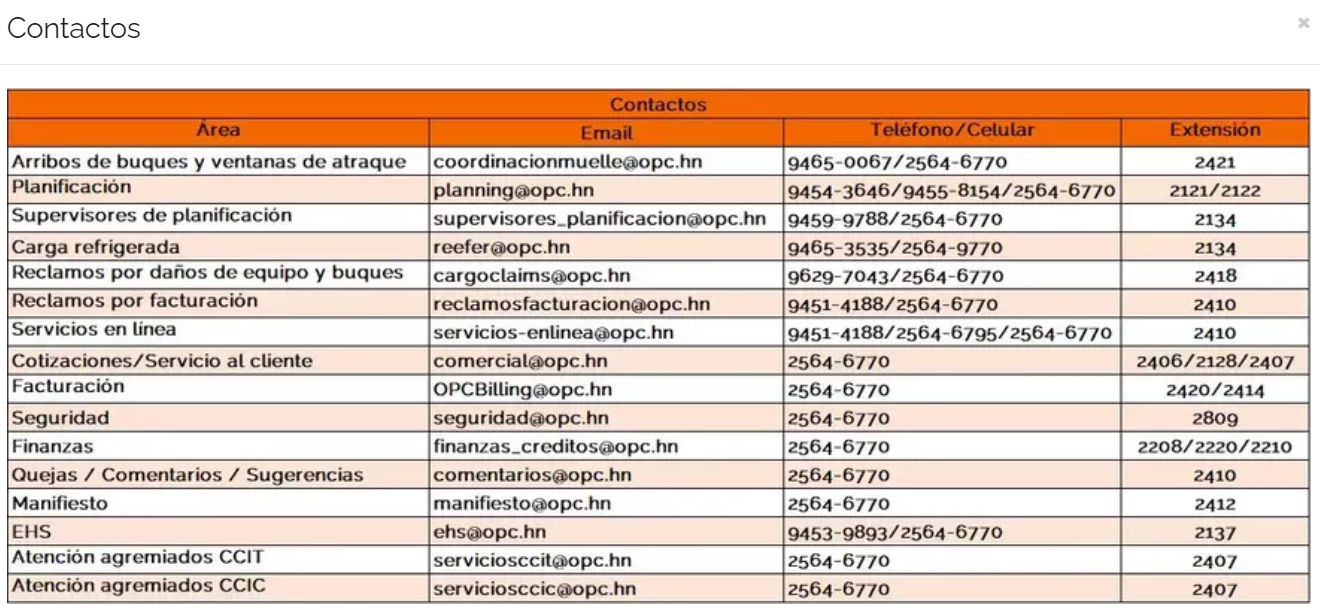

Description and contacts of the main companies

Port performance

|

Seasonal limitations |

||

|---|---|---|

|

Yes/No |

Period |

|

|

Rainy season |

Yes |

From August to November |

|

High import season |

Yes |

From January to May (Bulk cargo) From January to December (Containerized and general cargo) |

|

Other Comments |

June to November is hurricane season; The most critical time begins in September. |

|

|

Traffic figures for 2022 |

|

|---|---|

|

Ship calls |

1,564 |

|

Container traffic (TEUs) |

768,811 (Current capacity: 1,400,000 TEUs) |

|

Liquid, solid and general load figures 2022 |

|

|---|---|

|

Liquid cargo (TM) |

2,280,000 |

|

Solid Load (TM) |

3,100,000 |

|

General Cargo (TM) |

1,400,000 |

|

Handling type |

Total, landing (thousands of mt) |

Total, shipment (thousands of mt) |

Total (thousands of mt) |

|---|---|---|---|

|

General Cargo |

707.07 |

15.30 |

722.37 |

|

Contenerizada |

2,647.77 |

2,007.63 |

4,655.41 |

|

Liquid Bulk |

2,256.21 |

174.69 |

2,430.90 |

|

Solid Bulk |

2,897.32 |

1,439.09 |

4,336.41 |

|

Other |

76.48 |

204.73 |

281.20 |

|

Ro-Ro |

10.79 |

0 |

10.79 |

|

12,437.09 |

Unloading fees and terminal cargo handling charges

For more information on port fees and charges, please consult the following link: https://www.opc.hn/lib/PDF/Tarifario-OPC-01-enero-2023%20NM.pdf

Spring Specification

|

Type of Spring |

Quantity |

Long (m) |

Maximum depth (m) |

Feedback |

|---|---|---|---|---|

|

Liquid spring |

2 |

126 72 |

14 12 |

Texaco: Petrolium Liquid and some petrolium |

|

Container dock |

3 |

355 124 350 |

12 12 14.5 |

Container Cargo and ro-ro

|

|

Bulk dock |

2 |

201 323 |

12 12 |

Dry bulk and convencional cargo Dry bulk and ro-ro |

|

Tugs |

5 |

3 Tug boats 2000 HP (OPC) 2 (are out of service) |

||

|

Barges |

0 |

It is not currently counted in the port. |

Docks for handling general cargo

|

Type of cargo |

Dock identification |

|---|---|

|

Imports – Packed cargo |

Pier 4, 5A, 5B and 6 |

|

Exports - Packed cargo |

Pier 4, 5A, 5B and 6 |

|

Imports and Exports - RoRo |

Pier 4, 5A, 5B and 6 |

|

Other Imports |

Pier 1 and 1A (Liquid and some petrolium) Pier 2 and 3 (Bulk) |

Port Management Equipment

|

Team |

Available |

Total quantity and available capacity |

Feedback on current status and actual usage |

|---|---|---|---|

|

Quay crane |

Yes |

6

|

-Rubber-tired gantry cranes (RTGs) -Mobile harbor cranes (MHCs) |

|

Container crane |

Yes |

6 (60 MT) |

-Ship-to-shore cranes (STSs) |

|

Mobile cranes |

Yes |

4 |

|

|

Forklift for containers (Reachstacker) |

Yes |

19 |

|

|

Tractors for RoRo (Tugmaster / with head) |

Yes |

4 |

Roll MAFI Trailers 50-100 TN |

|

Grain elevator with packing machines |

No |

||

|

Transtainer |

No |

||

|

Forklift |

Yes |

26 |

6 (2 TM/5,000 lbs) 4 (Electric 2.5 TM) 1 (2.7 MT) 6 (3.6 MT/8,000 lbs) 4 (7 MT/15,000 lbs) |

Container handling facilities

|

Facilities |

20ft/40ft |

|---|---|

|

Availability for container handling |

Yes |

|

Container Handling Station (CFS) |

Yes |

|

Station for refrigerated containers |

Yes |

|

Other details about facilities |

Specific area for crossdocking operations. |

|

Daily load capacity (Containers per Day) |

5 vessels in line |

|

Number of stations for refrigerated containers (Connection points) |

1 |

|

Load capacity in Emergency |

NA |

|

Load capacity of crews per shift (Containers per Shift) |

NA |

Customs Guide

Customs clearance procedures at the Port of Puerto Cortés in Honduras are overseen by the Honduran Customs Administration, also known as the Dirección Adjunta de Rentas Aduanas. Below you will find a general guide on customs clearance procedures for imports and exports at the port:

- Obtain the necessary permits and licenses: Before you can import or export goods from Honduras, it may be necessary to obtain permits and licenses from various government agencies, depending on the type of goods being shipped. These may include the Ministry of Health, the Ministry of Agriculture and the Ministry of the Environment, among others.

- Submit import/export documentation: Once all necessary permits and licenses have been obtained, the importer or exporter must submit all required import/export documentation to the SAR. This documentation includes the commercial invoice, packing list, bill of lading and other relevant documents.

- Pay customs duties and taxes: The importer or exporter is responsible for paying all customs duties and taxes associated with the shipment. These fees may include import duties, value-added tax (VAT), excise duties and other fees.

- Cargo Inspection: SAR can inspect cargo to ensure compliance with all import/export regulations and to verify the accuracy of the documentation submitted.

- Cargo Release: Once all necessary customs duties and taxes have been paid and the cargo has been inspected, SAR will issue a release order allowing the cargo to be cleared for entry into or exit from the port. It is important to note that customs clearance procedures can be complex and may vary depending on the specific nature of the goods being imported or exported. Importers and exporters are advised to work with a licensed customs broker or freight forwarder to ensure compliance with all regulations and facilitate a smooth customs clearance process.

For more information on customs in Honduras, please refer to the following link: 1.3 Customs Information.

Terminal Information

Multipurpose Terminal

Also named Berth 4; is used to perform general cargo operations; and is located next to the port's largest warehouse, cargo is usually moved with the vessel's equipment, this terminal can also be used to carry out bulk operations, when available.

https://comercioexterior.la/puertos-maritimos/honduras/puerto-cortes/

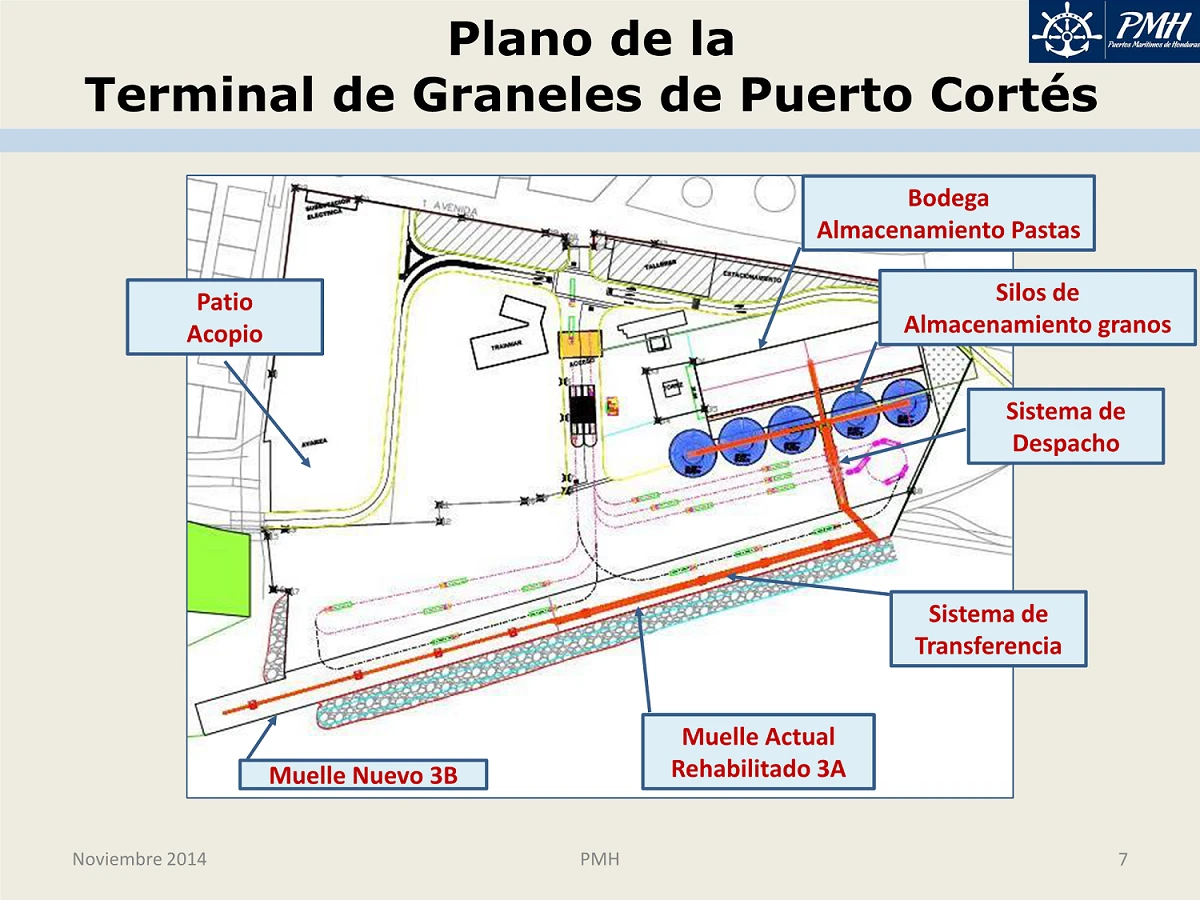

Grain Handling and Bulk Cargo

The Specialized Terminal of Honduras (TEH), is intended only for bulk handling; and within its facilities it has 5 silos with a capacity of 8,000 tons each; and are located near pier 3b, in the same way, the silos are connected to a berth by 2 conveyor belts, when the cargo ships arrive at this terminal, the merchandise is unloaded with; handholds, channels, mobile cranes or with the ship's equipment, whichever is considered to be faster operationally; The load is then placed on the conveyor belts and/or directly on the trucks.

PRIMARY STORAGE TERMINAL

|

Type of Storage |

Number of installations |

Area (m2) |

|---|---|---|

|

Packed cargo |

||

|

Refrigerated cargo |

1 |

4,135.23 Mts² 4200 MT |

|

General Cargo |

2 |

7,150.98 mts² 5,109.75 mts² |

Stevedores

It corresponds to the OPC to provide the services of unloading and / or loading of any type of cargo only of international transport, as well as the use of the infrastructure and port equipment required of the port terminal, including, for loading in containers:

(a) the loading/unloading service, including stowage/unloading;

(b) the lashing/unlocking service of containers on the ship;

(c) the transfer service between the side of the ship and the storage area;

d) the dispatch/reception service – in the storage area, yard and vessel; among others.

Information on territorial catchment area (Hinterland)

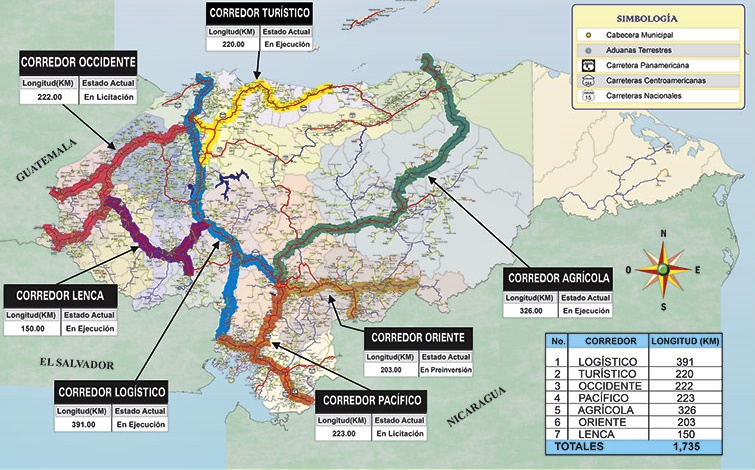

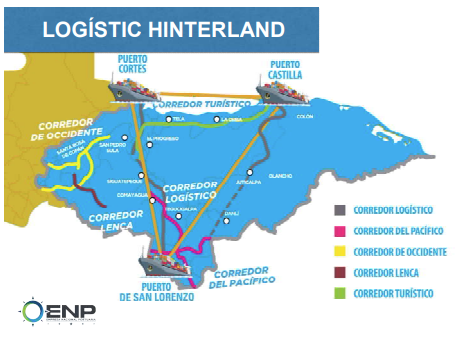

Honduras has 9 logistics corridors, the Logistics Corridor, the Central Corridor, the Dry Canal, the Agricultural Corridor, the Tourist Corridor, the Eastern Highway, the Lenca Corridor and the Western Corridor, which connect and facilitate the transport of merchandise through the national territory, and the Central American region.

The main road connections are through the CA-5 route, which crosses the Honduran territory in a north-south direction and connects the main centers of production and consumption of the country (Puerto Cortés-San Pedro Sula-Tegucigalpa and the extreme south), and the CA-1 route, second route in importance and Pan-American connection (Pacific Corridor) with El Salvador and Nicaragua.

The largest is the Logistics Corridor, has a length of 391 km and connects the ports of Amapala and Henecán in the Pacific with Puerto Cortés in the Atlantic, and is fundamental for Central America in the transport of goods, mainly destined for the East Coast of the United States.

The Logistics, Dry Canal, Agricultural, Lenca, Western and Pacific corridors strategically cross the national territory and total a length of 1,182 kilometers.

These connections with the world, through maritime port, airport, and land infrastructure, added to the coordinated management of borders and urban logistics, and the promotion of an offer of logistics services, will position Honduras as a world-class logistics HUB by 2030.

Port Security

Within this advance in modernization and development, the OPC company has turned the issue of security into one of its main pillars in its management, managing to transform Puerto Cortés into one of the safest ports in the region.

It is identified as the only terminal in the region that has the Container Security Initiative (CSI), granted by the US Customs and Border Protection (CNP)

This initiative allows containers destined for the United States to arrive pre-released by the authority, which implies a lower risk to the Customs Service of that country, and, therefore, lower costs for cargo at destination, translated into greater security and competitiveness for exporters who use the Puerto Cortés terminal.

|

Safety |

|

|---|---|

|

ISPS Compliant |

Yes |

|

Current ISPS level (Level 1 = Normal, Level 2 = Heightened, Level 3 = Exceptional) |

1 |

|

Police boats |

Yes |

|

Fire trucks |

Yes |