2.1 Colombia Port Assessment

Colombia has four major ports, of which Barranquilla, Cartagena and Santa Marta are located on the Atlantic coast and Buenaventura at the Pacific. Atlantic coast ports connect the country with Central America, North America and Europe while Buenaventura serves the trade with the west coasts of the Americas and Asia. Cartagena qualifies as a transshipment hub for containers. The entrance channels to Barranquilla and Buenaventura are subjected to sedimentation, restrictions to vessels’ draft might apply.

Additionally, to the major terminals both Colombian coasts feature a large number of private jetties and small port facilities for (mostly) local trade, e.g.: Puerto Zuniga, Puerto Prodeco, Pozos Colorados, Puerto Bolivar, Cienaga, Turbo, Pindo, Tumaco, San Andres Island and Tolu.

2.1.1 Colombia Port of Buenaventura

Port Overview

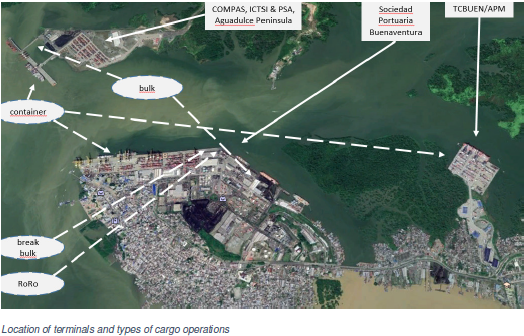

Buenaventura offers one multi-purpose terminal including a container terminal - Sociedad Portuaria Buenaventura (SPB) – a bulk and a container terminal located to the north (Aguadulce) of SPB and a container terminal east (TCBUEN) of SPB. The entrance channel faces constant sedimentation – different values were given for the draught restriction. Something like 9 m at low tide seems likely, a tidal range of approx. 4 m would permit vessels entering with up to 13 m draught at high tide. Prior to chartering a vessel present conditions must be verified with the pilots. Pilotage is compulsory for all ships of more than 200 tons and available on a 24-hour basis.

The pilot will board the vessel one mile from shore sea buoy #1; Approx. Duration of whole maneuver: 2 hours. The access channel to all three terminals has a length of 31.5 kilometers, equivalent to 17 nautical miles. It is recommended to take special care in navigation during transit of the inner bay, since it is common to find large trunks in the canal, which may hinder maneuvers. During the rainy season the visibility decreases, so is important to take a special care because there is a high traffic of fishermen.

Buenaventura handles the largest cargo volume of all Colombian ports. Most of the port services areprovided by private companies.

As road access might be an issue: Cargo movements through the Aguadulce terminal do not have to traverse the town of Buenaventura.

Port website: http://www.sprbun.com/

Key port information can also be found at: http://www.maritime-database.com/port.php?pid=3603

|

Port Location and Contact |

|

|---|---|

|

Country |

Colombia |

|

Province or District |

Valle del Cauca |

|

Nearest Town or City with Distance from Port |

Buenaventura (0 km) |

|

Port's Complete Name |

Sociedad Portuaria Regional De Buenaventura S.A. |

|

Latitude |

3.892923 |

|

Longitude |

-77.067902 |

|

Managing Company or Port Authority |

Sociedad Portuaria Regional De Buenaventura S.A. |

|

Management Contact Person |

Juan Pablo Cepeda (Manager) |

|

Nearest Airport and Airlines with Frequent International Arrivals/Departures |

Alfonso Bonilla Aragón International Airport in Cali. American Airlines, TAME, KLM & United Airlines. |

Port Picture

Description and Contacts of Key Companies

The following passages refer to Buenaventura’s multi-purpose terminal operated by Sociedad Portuaria Buenaventura (SPB).

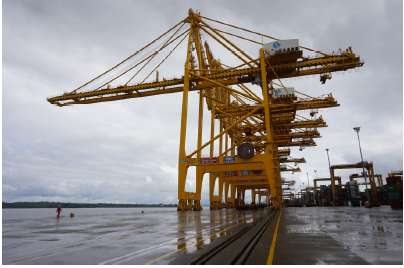

In the SPB a container terminal, with a docking line of 1,050 m; equipped with six (6) gantry cranes, one terminal with reach stakers on post-Panamax ship to shore rails and three (3) multipurpose mobile cranes, with forklifts of different capacities for container movement with a 525 m berthing line; 2 multipurpose terminals, one with a 204 m berthing line equipped with 3 mobile cranes with the capacity to move up to 104 tons, and another multipurpose, for the handling of solid bulk (coal), liquid bulk and general cargo with a berthing line 190 m.

The two terminals Aguadulce (container, bulk) and TCBUEN (container) are described at the end of this chapter.

COMPAS: Grupo Argos and Southern Port Holding Corp. created on December 1, 2012 COMPAS S.A., the only network of multipurpose public ports in Colombia. With two port terminals in Cartagena, one in Buenaventura, one in Barranquilla, one in Tolú and two in Panama and Houston U.S.A. This terminal has a public operation, is located on the Island of Cascajal and has the possibility of accessing the Pacific railway corridor. It has the most efficient transfer machining system in the country, with 37,676 square meters of concession area, a draft of 10.5 meters of BW and a storage capacity of 47,200 tons. It specializes in the mobilization, efficient storage and dispatch of bulk solids, grains and by-products, while preserving their quality.

ALMAGRARIO: port operator with experience and track record for handling all types of cargo, bulk or general cargo. It is qualified as the port's primary operator, with a storage capacity of 32,000 tons in each silos plant. The unloading is done through suction, spoon and / or hopper methods. The port has 4 bulk docks, 48 silos and 28 mezzanines, a MIAG suction tower with two pumps, with a capacity of 200 tons / hour. It has two 80 ton truck scales each and two electronic step scales.

OPERCAR: Authorized port and logistics operator for cargo handling in the public and private ports of Barranquilla, Cartagena, Santa Marta and Buenaventura. It has a diversified portfolio of services for the handling of general cargo, iron products andsteel, containers, solid bulk, project cargo, rolling cargo, among others. Specialists in the management of oil and gas pipelines, including the supply of lifting equipment, specialized hooks (shoes), inspection tables and lumber for storage.

For more information please see this link: 4.4 Colombia Port and Waterways Company Contact List.

Port Performance

The main port of Buenaventura handles containers, bulk and general cargo on 14 berths - of which 12 are operated by Sociedad Portuaria Buenaventura (SPB) and 2 under concession (COMPAS). SPB’s dock has a length of 2,000 meters. The port shares its location with the city center on an island – connected to the mainland by one bridge (Puente el Piñal, 3 lanes in each direction) only.

The Port has a regulation for humanitarian aid where humanitarian cargo will have priority in the event of a declared national emergency.

|

Seasonal Constraints |

||

|---|---|---|

|

Occurs |

Time Frame |

|

|

Rainy Season |

Yes |

April to May; October to November, although this can vary considerably. |

|

Major Import Campaigns |

No |

Increased volumes of consumer goods during October and November. |

|

Other Comments |

N/A |

|

|

Handling Figures for 2019 |

|

|---|---|

|

Vessel Calls |

1,458 |

|

Container Traffic (TEUs) |

1’200,000 TEUs |

|

Handling Figures Bulk and Break Bulk for 2019 |

|

|---|---|

|

Bulk (MT) |

1,624,639 |

|

Break bulk (MT) |

4,370,861 |

Discharge Rates and Terminal Handling Charges

www.sprbun.com/web/portal/tarifas/Servicios Portuarios

www.sprbun.com/web/portal/tarifas/Servicios Logísticos

Berthing Specifications

|

Type of Berth |

Quantity |

Length (m) |

Maximum Draft (m) |

|---|---|---|---|

|

Conventional Berth |

2 |

204 m and 190 m |

9.14 |

|

Container Berth |

9.14 |

Total 1050 m |

9.44 |

|

Silo Berth |

3 |

Total 525 m |

7.62 |

|

Berthing Tugs |

Yes |

||

|

Water Barges |

Yes |

(Berths N°2 a N°8 for containers, N°10 a N°12 bulk, N°9 multicargo, N°14 liquid cargo , N°13 Under concession for Grupo Portuario S.A. y N°1 operated by Compass S.A.)

For further information on berths, please see the following link: http://www.sprbun.com/documentos/ventanas_de_atraque_en.pdf

General Cargo Handling Berths

|

Cargo Type |

Berth Identification |

|---|---|

|

Imports - Bagged Cargo |

9 to 12 |

|

Exports - Bagged Cargo |

9 to 12 |

|

Imports and Exports - RoRo |

9 to 12 |

|

Other Imports |

Cntrnrs 2 to 8 |

Port Handling Equipment

The private company or concessionaire manages the port concession granted by the government. The services offered are piloting, tugs, fuel, lubricants, supply of provisions, berthing. Boat services: repair of mechanical, electrical, hydraulic and cooling systems; Cargo handling (loading and unloading of ships), medical, dental and immigration services for ship crews, storage tanks, monitoring and control of containers for transshipment; consolidation and deconsolidation of LCL containers, solid waste and wastewater treatment, steel, containers, solid bulk, project cargo, rolling cargo, among others. Specialists in the management of oil and gas pipelines, including the supply of lifting equipment, specialized hooks (shoes), inspection tables and lumber for storage.

|

Equipment |

Available |

Total Quantity and Capacity Available |

Comments on Current Condition and Actual Usage |

|---|---|---|---|

|

Dockside Crane |

Yes |

2 (50 MT) and 2 (60 MT) |

Actual usage |

|

Container Gantries |

Yes |

13 (40 to 62 MT) |

3 Neo-Panamax and 10 Panamax, rail mounted |

|

Mobile Cranes |

Yes |

3 (100 & 104 MT) |

Multipurpose mobile cranes |

|

Reachstacker |

Yes |

16 (40 & 30 MT) |

Actual usage |

|

RoRo Tugmaster (with Trailer) |

No |

N/A |

N/A |

|

Grain Elevator with Bagging Machines |

Yes |

4 (1 for 700 MT / hour, 2 for 300 MT / hour and 1 for 220 MT / hour) |

Grain suction |

|

Transtainer |

Yes |

22 (60 MT) |

Rubber tire Gantry Cranes for yard handling |

|

Forklifts |

Yes |

10 |

Forklifts with different capacities for containers handling |

Container Facilities

Berths 2 to 8 (Containers) Berth Line: 1050 meters length; Equipped with 13 Gantry cranes (STS), 3 of those Post Panamax and 3 multipurpose mobile cranes, 22 transtainer (RTG), reachstacker and forklifts with different capacities for containers handling. SPB has a specialized container terminal (Buenaventura SA - TECSA). The Post Panamax STS can move 35 Containers / Hour. According to SPB the container terminal was working at approx. 60 % of its capacity in 2018.

SPB container operations

|

Facilities |

20 ft / 40 ft |

|---|---|

|

Container Facilities Available |

440 meters long quay, allows berthing for 2 large vessels simultaneously or 1 Panamax vessel, 14 meters depth at low tide. Attend up to 260,000 TEUS per year. |

|

Container Freight Station (CFS) |

Weighing system (with dynamic scales), Load / unloads (Updated technology for full and for empty containers) Storage (safe areas), cargo inspection and cargo movement, operations on line (conditions and status of cargo). 19 hectares for storage with a capacity to store up to 8,000 TEUS (in 2018 a figure of 26,800 TEU was given by SPB) simultaneously. Capacity 768 TEUS, Sortie Container service. |

|

Refrigerated Container Stations |

Monitoring technical conditions, connection and disconnection of reefer containers to the electrical net, power supply (Electrical voltage is handled for the different types of containers) |

|

Other Capacity Details |

N/A |

|

Daily Take Off Capacity |

347 |

|

Number of Reefer Stations |

384 |

|

Emergency Take-off Capacity |

N/A |

|

Off take Capacity of Gang Shift |

N/A |

Customs Guidance

DIAN is the main government customs entity in Colombia, when an import or export exceeds USD 1,000, use of a customs broker for this process is recommended.

Customs regulations per decree 2685 and Muisca regulations stipulate that:

- All cargo on board a vessel, with destination Colombia must be manifested.

- The manifest and bills of lading have to be registered to Customs systems (Muisca) 12 hours prior to ship's arrival.

- Cargo not covered by manifest may not be discharged. If discharged it will be immediately confiscated by Customs.

The processing by Customs may take 1-3 days maximum, depending on the level of inspection. In Colombia the customs authorities is the most influential institution in the process of nationalization, dustoms procedures can be affected by delays or technical problems by the DIAN system when making records, or documentary procedures unrealized by the importer / exporter. It is recommended to do constant cargo tracking and obey the instructions of the officials, as long as they are legal and fair.

DIAN have a special type of import procedure for emergencies, under this mode delivery to the end user may do without any prior processing.

For more information on Customs in Colombia, please refer to: 1.3 Colombia Customs Information.

Terminal Information

Multipurpose Terminal

Berth 9: (Multipurpose) Berthing line of 204 meters, Equipped with three multi-purpose mobile cranes with a capacity to handle 104 tons.

Berth14: Berthing line: 190 meters. Multipurpose terminal for handling bulk solids (Carbon), liquid bulk and general cargo, for handling coal stacking area is 4,500 m2 and 16,800 tons of weight.

The liquid bulk area is equipped with 14 independent and segregated lines for simultaneous pumping, with a modern fire extinguishing system and crane for handling all types of pipelines.

Grain and Bulk Handling

Grain elevator at SPB

Grain silos at SPB (outside port perimeter)

At berths 10 to 12 bulk cargo is handled by Almagrario. Equipped with mechanical and pneumatic bulk unloaders; Total efficiency: 1,520 tons per hour.

Equipment for bulk solids:

- Electro Hydraulic scoop; Capacity 35 m3, density of bulk material 0,8 Ton / m3, efficiency 450 Ton/hr. Dimensions: Open (Width 5.6 m x Length 4.72 m) Close (Width 4,44 mts x Length 4,72 mts).

- Dual gate hopper of 70m3. Discharging direct onto truck, or transfer to silos and / or storage warehouses at the port.

Main Storage Terminal

Service of provision of covered or open-air, warehousing space to store import, export, domestic or transit cargo within the port's facilities.

OPP Graneles S.A is operating a specialized warehouse for coffee (8,682 m2) and one for sugar (20,835 m2).

- Liquids Bulk Storage capacity: More than 230,000 cubic meters.

- Solids bulk warehousing capacity: More than 172,500 tons capacity in silos warehouses and covered areas.

- 20 Silos – Capacity 75000 MT

- 6 Warehouses – Capacity 50000 MT

- 2 Eco Warehouses – Capacity 5000 MT

Company: Almagrario

- 48 Silos – Capacity 600 MT & 550 MT

- 26 Silos – Capacity 39000 MT

|

Storage Type |

Number of Storage Facilities |

Area (m2) |

|---|---|---|

|

Bagged Cargo |

1 (Warehouse) 2 (yards) |

Warehouse (5515 m2) Yards (4200 m2) |

|

Refrigerated Cargo |

At the terminal container |

768 TEU's |

|

General Cargo |

10 (Warehouse) and shed |

Warehouse (69947) Shed (30235 m2). |

Stevedoring

Stevedoring operation is made by private companies, classified and regulated by the national government. The ratio and ranking of the operators is performed in accordance to the type of activities and services they provide to the terminals (cargo handling, pilotage, towage, dredging, port storage and other activities).

Hinterland Information

Land transporters arriving at the port of Buenaventura are offered the following services:

- Terrestrial Programming Center - CPT: It is an alternative by means of which a transport company requests the port by electronic means to load containers with imported loads, indicating the estimated date and time. Allows planning and scheduling of resources for trucks to enter the Maritime Terminal without waiting times, confirming the provision of the service also by electronic means.

- Scale service: For weighing loaded and empty trucks.

- Creation of A-check visits: Carried out by the Transport Companies for the entrance of the trucks to the Maritime Terminal.

- Container inspection: This activity is carried out on trucks that move full and empty containers.

- Operational equipment: Front lifts, reach staker and RTG for loading and unloading trucks.

- SISE: Integrated Electronic Security System for truck traceability.

Near the port can be found the free trade zone (Defined area of a country where it enjoys certain tax benefits, such as exemption from payment of import duties or certain taxes or regulation).

Port Security

|

Security |

|

|---|---|

|

ISPS Compliant |

Yes |

|

Current ISPS Level |

Level 1 |

|

Police Boats |

Yes |

|

Fire Engines |

Yes |

Access control system

Implemented to warranty persons entering the Port are fully identified and to hinder unauthorized access. This control is performed by 62 biometric readers, 18 full body and half-body rotating stands, 23 security fences at vehicle access points, all controlled by a server housing detailed data on the port population.

Perimeter Control System

Implemented in order to prevent intruders access through the outside perimeters of the port facilities, the system consists of 4,800 meters of sensor cable controlled by 23 processors that interpret the signals received, and then transmit information to the control center. The center immediately complements intruder detection with the video equipment available in the zone to immediately alert security personnel and make this information available to them.

Closed Circuit TV

The purpose of the system is to monitor and record all Port operations and activities, it has 370 fixed and panning cameras distributed throughout the port and 21 digital recorders to store, security events 24 hours/day. The system includes special equipment for monitoring the internal navigation channel under any visibility condition and includes 75-day average recording time.

Armed security personnel

As a complement to the Integrated Electronic Security System, the Port has a team consisting of 265-armed security guards and 6 patrol units, by land and sea. They are fully equipped with the necessary devices to maintain communication between the different systems and personnel monitoring security.

Terminal Aguadulce

Opposite the bay of Buenaventura the peninsula of Aguadulce features a jetty for dry bulk and container handling. The terminal was not assed in situ. An interesting aspect of Aguadulce is the access road that avoids Buenaventura city and Puente el Piñal.

Container terminal of ICTSI and PSA, Aguadulce Peninsula

Container Terminal

The container terminal is operated by ICTSI and PSA, currently equipped with 4 Post Panamax rail mounted gantry cranes (RMG's) and about 10 rubber-tired gantry cranes (RTG's) for yard movements. Depth along the 1,200 m long jetty is given with 14.5 m (low tide). Satellite imagery shows 9,000 m2 paved container yard and a container freight station.

Dry Bulk Terminal

Bulk operator COMPAS claims (http://www.compas.com.co/en/terminals/aguadulce) offering the capacity of receiving vessels of up to 80,000 tons and a depth of 15 meters at low tide. Apart from mechanized export of coal the terminal counts with a grain elevator, a mobile port crane, 4 vertical silos with a capacity of 6.500 ton each and 2 additional warehouses of 2.300 sqm each. Total storage capacity is given as 25,200 tons.

Container Terminal TCBUEN

Container terminal TCBUEN of APM

The container terminal is operated by APM, equipped with 4 Post Panamax RMGs (rail mounted gantry cranes) and 13 RTGs (rubber-tired gantry cranes for yard movements). Depth along the 440 m long jetty is given with 14 m (low tide) the entrance channel leading to the jetty being dredged to 12.5 m. Satellite imagery shows 112,000 sqm. paved container yard and 5 warehouses. Shipping lines calling TCBUEN include APL, HAPAG-LLOYD, K-LINE, MAERSK, MOL, NYK and SEALAND. The terminal is situated east of Buenaventura city centre, access avoids the possible bottleneck Puente el Piñal.

Commercial aspects

In the national context, the Bay of Buenaventura maintained leadership in the second half of 2019 with a 42% share in the total mobilization of tons with respect to the other ports in the country. Regarding the Buenaventura Regional Port Society, within the port node where it is located, its participation corresponds to 54%.

Containers

SPRBUN continues to lead the participation in container loading in Buenaventura Bay with a mobilization of 170,696 Teus, out of a total of 389,630 Teus mobilized in the Buenaventura port node. The loss of international transshipment cargo is noteworthy, as a result of differential conditions in the depth of the access channel to the Bay of Buenaventura, which came to be managed by the Posorja Terminal in Ecuador.

Information Technology Management

During the second semester of 2019, the Regional Port Society of Buenaventura, through its Information Technology Management, continued the strategic plan for digital transformation through innovative technological solutions, ensuring business continuity, management and security of IT services for its users and clients.

2.1.2 Colombia Port of Barranquilla

Port Overview

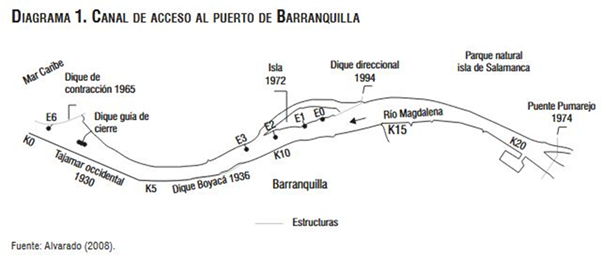

The facilities of the Port of Barranquilla are located along the Magdalena River. Most of the docks and piers are private and are not intended for cargo handling by third parties. The multipurpose Maritime Terminal and BITCO container terminal are operated by Sociedad Portuaria Regional de Barranquilla S.A. (SPRB). Both are located approximately 10 nautical miles (18 km) upstream on the west bank of the river. Additionally, a multipurpose terminal operated by COREMAR is located on the opposite coast near the Palermo settlement.

A spout at the mouth of the river reduces the depth to less than 9m, which currently must be constantly dredged to achieve the 11m depth required. Currently, the Panamax ships with 50,000 MT of cargo capacity can transport a maximum of 35,000 MT to reduce draft. Practical piloting and tugging is mandatory for all ships over 200 tons, both available 24 hours. The pilot will board the ship at the pre-established point approximately 3 nautical miles from the mouth of the river (Bocas de Ceniza). Another half mile upstream is the new Pumarejo Bridge (Length 3,237 m Width 38 m.) Inaugurated in December 2019 with this new infrastructure, the height of the ships that can pass underneath is 45 meters.

Port website: http://wwwpuertodebarranquilla.com/

Key port information may also be found at: http://www.maritime-database.com

|

Port Location and Contact |

|

|---|---|

|

Country |

Colombia |

|

Province or District |

Región Caribe, Atlántico |

|

Nearest Town or City with Distance from Port |

Barranquilla, 4 km |

|

Port's Complete Name |

Puerto de Barranquilla Sociedad Portuaria |

|

Latitude |

10.967273 |

|

Longitude |

-74.765456 |

|

Managing Company or Port Authority |

Sociedad Portuaria Regional de Barranquilla S.A. |

|

Management Contact Person |

René Puche Restrepo (Manager) |

|

Nearest Airport and Airlines with Frequent International Arrivals/Departures |

Aeropuerto Internacional Ernesto Cortissoz |

Port Picture

Description and Contacts of Key Companies

The companies operating within the port area are the largest and most active in the supply chain, most of them are private companies due to recent policies of the present administration. For more information on port contacts, please see the following link: 4.4 Port and Waterways Contact List.

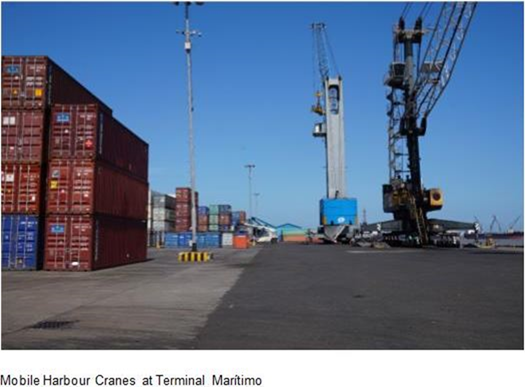

Port Performance

The maritime terminal on the west bank is one of the largest multipurpose terminals in all of Colombia, operating a 1,000 m long pier. The containers are handled by mobile cranes in the main terminal and gantry cranes in the affiliated terminal BITCO CONTAINER TERMINAL, 500 m downstream. It has 5 of the 12 warehouses, connected to the automatic grain unloading system, 132,000 MT of storage capacity (plus 77,000 tons outside the port perimeter) for grain, with discharge rates of up to 8,000 tons / day. The Port of Barranquilla handled 1.6 Million tons of grain in 2017. Bagging operations are carried out regularly throughout the berthing area. At the Maritime Terminal, controlled temperature storage is available through a modern 3,200m2 refrigerated warehouse.

|

Seasonal Constraints |

||

|---|---|---|

|

Occurs |

Time Frame |

|

|

Rainy Season |

Yes |

From May to October |

|

Major Import Campaigns |

No |

The high season of trade, considered in the months of October and November, the operators are preparing for Christmas. |

|

Other Comments |

N/A |

|

|

Handling Figures for 2018 |

|

|---|---|

|

Vessel Calls |

737 |

|

Container Traffic (TEUs) |

Aprox. 100,000 TEUS |

For more information please go to: https://www.supertransporte.gov.co/

As historical, the year 2018 can be qualified for the Port of Barranquilla, Sociedad Portuaria, who report a cargo movement of 5,235,881 tons, a figure that it had never reached in its 82 years of operation.

Discharge Rates and Terminal Handling Charges

For information on port rates and charges, please see the following link: http://puertodebarranquilla.com/index.php/tarifas-2/

*Terminal Handling Charges (THC) calculation template by private Shipping Line Hamburg Süd: https://ecom.hamburgsud.com/ecom/es/ecommerce_portal/tariffs_and_surcharges/thc_calc/ep_thc_calculator.xhtml

Berthing Specifications

|

Type of Berth |

Quantity |

Length |

Maximum Draft |

Comments |

|---|---|---|---|---|

|

Conventional Berth |

2 (berths 3 and 4) |

Total 1,058 m. 6 positions |

8.80 m |

According to the operator |

|

Container Berth |

2 (berths 1 and 2) |

Total 1,058 m |

8.80 m |

According to the operator |

|

Silo Berth |

2 (berths 5 and 6) |

Total 1,058 m |

8.80 m |

According to the operator |

|

Berthing Tugs |

2 (berths 1 and 2) |

12.2 m |

According to the operator |

|

|

Water Barges |

2 (berths 2 and 3) |

8.2 m- 11.2 m |

According to the operator |

Additional dock for river operations, 550 m long, depth given 12 feet.

General Cargo Handling Berths

|

Cargo Type |

Berth Identification |

|---|---|

|

Imports - Bagged Cargo |

n/a |

|

Exports - Bagged Cargo |

n/a |

|

Imports and Exports - RoRo |

n/a |

|

Other Imports |

n/a |

Port Handling Equipment

|

Equipment |

Available |

Total Quantity and Capacity Available |

Comments on Current Condition and Actual Usage |

|---|---|---|---|

|

Dockside Crane |

Yes |

2 (100 tons ea.) |

Gottwald |

|

Container Gantries |

Yes |

3 (30 tons) |

Straddle Carriers |

|

Mobile Cranes |

Yes |

2 (124 tons) |

LIEBHERR LHM 420 |

|

Reachstacker |

Yes |

17 (7 a 18 tons) |

n/a |

|

RoRo Tugmaster (with Trailer) |

No |

n/a |

n/a |

|

Grain Elevator with Bagging Machines |

Yes |

1 (280 tons x hour) |

n/a |

|

Transtainer |

No |

n/a |

n/a |

|

Forklifts |

Yes |

n/a |

Service operated by private subcontractors. |

Container Facilities

|

Facilities |

20 ft / 40 ft |

|---|---|

|

Container Facilities Available |

12 hectares of container yard, capacity 6,064 TEUS, 116 inspection areas |

|

Container Freight Station (CFS) |

2,800 m2 |

|

Refrigerated Container Stations |

186 |

|

Other Capacity Details |

n/a |

|

Daily Take Off Capacity |

n/a |

|

Number of Reefer Stations |

186 |

|

Emergency Take-off Capacity |

n/a |

|

Off take Capacity of Gang Shift |

300 |

Customs Guidance

DIAN is the customs authority in Colombia. If the commercial value of an import exceeds USD 1,000.- it is recommended to hire the services of a customs agent for the procedure. The customs procedures, by decree 2685 and MUISCA regulations stipulate that:

- All cargo on board a ship bound for Colombia must be indicated on the cargo manifest.

- Manifests and BLs must be registered with the Customs system (MUISCA), twelve (12) hours prior to the arrival of the ship.

- Any cargo not indicated in the cargo manifest may not be landed. If it were, it would be immediately confiscated by the customs authority.

The customs procedure can take from 1 to 3 days, depending on the level of inspection assigned. In Colombia, the customs authority is the most influential institution in the nationalization process. Customs procedures may be affected by delays or technical problems in the DIAN system, verifying its statistics or verifying documentary procedures omitted by the importer / exporter. It is recommended to constantly monitor the cargo and obey the instructions of the customs officials as long as they are legal and correct.

DIAN foresees special import procedures in case of emergencies. Under this modality the load can be consigned to the final recipient without any process.

For more information on customs in Colombia, please see the following link: https://www.dian.gov.co/

https://muisca.dian.gov.co/WebArancel/DefConsultaEstructuraArancelaria.faces#

Terminal Information

Multipurpose Terminal

General cargo is handled through one (1) mobile port crane and self-supporting boom of the ship, especially at docks 3 and 4.

Grain and Bulk Handling

The grain can be maneuvered through the grain elevator, achieving up to 550 tons / hour, connected to the five (5) sheds or by collection. The unloading capacity using the four (4) spoons (crane) and delivery in truck hopper is up to 8,000 tons / day, as indicated. The terminal has 12 front loaders, 3 backhoe loaders, 12 Shute type equipment and 11 electrohydraulic spoons. In addition, there are six (6) warehouses with a total capacity of 77,000 tons located outside the port perimeter. Almagrario is the largest operator of bulk cargo within the terminal.

Main Storage Terminal

|

Storage Type |

Number of Storage Facilities |

Area (m2) |

|---|---|---|

|

Bagged Cargo |

12 |

Total warehouse area 40,384 m2 (includes 5 warehouses connected to the grain elevator by suction). |

|

Refrigerated Cargo |

1 Cold Warehouse |

3,200 m2 |

|

General Cargo |

4 Warehouses |

18,835 m2 covered, 35,000 m2 open |

Container Terminal BITCO, SPRB

Since October 2018, the BITCO Terminal is operated by SPRB, under the same administrative modality as the Maritime Terminal (http://www.bitco.puertoenlinea.com.co/other/WhoAreWE.xhtml). There are two (2) piers with a total length of 300m, north pier 180m long and indicated depth of 12m, southern pier 120m long with indicated depth of 12.5m. The unloading at the north quay is carried out by means of three (3) gantry cranes. The container yard has 37,000 m2 with a capacity of 2,900 TEU's and a 2,000 m2 warehouse.

Multipurpose Terminal COREMAR, Palermo

The Coremar terminal is operated by Sociedad Portuaria Palermo S.A. Its main activity consists of the movement of general cargo, containers and bulk. The cargo is handled by the ship's self sustained cranes and a mobile port crane.

Discharge Rates and Terminal Handling Charges (THC): http://www.palermosociedadportuaria.com/en/rates.cfm.

Stevedoring

Stowage and stevedoring operations are carried out by private companies, classified and regulated by the state. The ratio and ranking of operators is determined according to the type of activities and services they provide to the terminals (cargo handling, piloting, practical, tug, dredging stored in port and others)

Hinterland Information

Thanks to the Magdalena River, the country's goods can be transported to and from the Barranquilla port to leave or enter the country. The port and surrounding industries provide the majority of employment opportunities in the city. From Barranquilla there is an immediate road connection to the main cities of the country and to the main cities of Venezuela. The city is located in the enclave of the two main trunk roads in the country: the Troncal del Magdalena, which begins in Bogotá and ends in Barranquilla, and the Troncal del Caribe, which begins in Paraguachón (border with Venezuela) and ends in Medellín , a road that passes through the city. Both trunks also connect to Cali and the west of the country through the Troncal de Occidente (also called Vía Panamericana), which ends at the border with Ecuador.

Port Security

A 24-hour surveillance along the entire length of the river between the mouth and the terminal, allows local authorities to provide a better security service to ships in the port, as well as pilot scheduling, when navigating within the navigation channel. and, finally, it also helps to reduce any possible piracy to vessels anchored in the middle of the current. The Port of Barranquilla acquired the first non-intrusive inspection equipment inside a terminal, these high-tech devices consist of a cargo scanner, a pallet and package scanner, and a trace scanner (explosives and chemicals detection device). With the use of scanners, inspection times by supervisory authorities are expected to exceed 24 hours, which takes an average physical inspection of 15 minutes, making the inspection non-intrusive.

|

Security |

|

|---|---|

|

ISPS Compliant |

Yes |

|

Current ISPS Level |

1 |

|

Police Boats |

No |

|

Fire Engines |

No |

2.1.3 Colombia Port of Cartagena

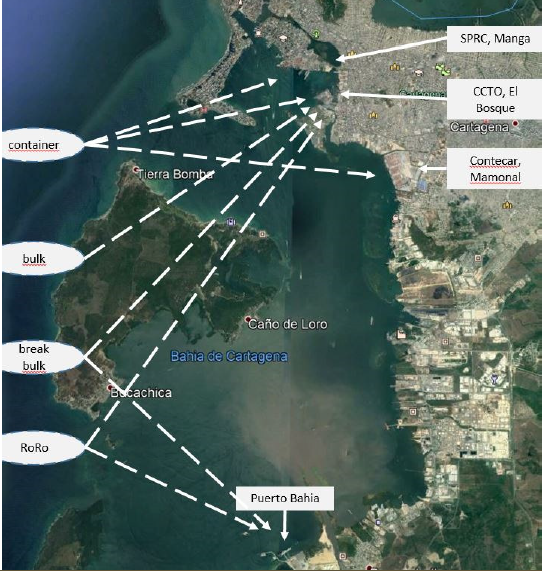

Port Overview

Located in the north-western part of Colombia Bahía de Cartagena is the largest port on the Caribbean coast. It is very close to the major transoceanic routes through the Panama Canal, several container shipping lines use Cartagena as transshipment hub. The port facilities of Cartagena are situated at the shores of a natural bay, sheltered from all directions and surrounded by the city. Minimum depth in the Bocachica entrance channel to the bay is 14.7 m (low tide). Tide range approx. 0.3 m.

Note: Pilotage is compulsory for all ships of more than 200 tons. Pilotage is available on a 24-hour basis. The pilot will board the vessel one (1) mile from Sea Buoy. Distance from pilot station to the port is 9 miles. Maneuvers of large vessels are subject to previous authorization from the harbor master office, the authorization must be requested at least 48 hours in advance.

The three mayor terminals handling cargo in Cartagena are:

Contecar and Manga are container and cruise terminals operated by Grupo Puerto del Cartagena at international operational standards and are equipped to handle Post-Panamax vessels. 3 Mil. TEUs were handled in 2017 by the two terminals – mostly transshipment cargo with a local percentage of only 25% thus creating low gate throughput relatively to terminal activity.

Cartagena Container Terminal Operator CCTO (http://www.ccto.com.co) is the new joint venture between APM Terminals, a world-renowned company in the port industry, and the Colombian-based port and terminal operator, Compañía de Puertos Asociados S.A. (Compas S.A.) www.compas.com.co. CCTO manages and operates Compas S.A.'s existing multipurpose facility. in Cartagena, Colombia, which includes an annual production capacity of 250,000 TEU and 1.5 million tons of general cargo.

Port website: https://www.puertocartagena.com/

http://www.apc.es/webapco/

In the southern part of the bay of Cartagena, a large-scale multipurpose terminal began operating in 2015 - Puerto Bahía https://www.puertobahia.com.co/

Key port information may also be found at: http://www.maritime-database.com

|

Port Location and Contact |

|

|---|---|

|

Country |

Colombia |

|

Province or District |

Bolivar |

|

Nearest Town or City with Distance from Port |

Cartagena (4.8 km) |

|

Port's Complete Name |

Sociedad Portuaria Regional de Cartagena |

|

Latitude |

10.406309 |

|

Longitude |

-75.528388 |

|

Managing Company or Port Authority |

Group Puerto de Cartagena |

|

Management Contact Person |

Alfonso Salas Trujillo (Manager) |

|

Nearest Airport and Airlines with Frequent International Arrivals/Departures |

Aeropuerto Rafael Nuñez Airport - Cartagena Latam, Avianca American Airlines, Air Italy, Jet Blue, Spirits, Can Jet, Air Pullmantur, Finnair, Blue Panorama Airlines, Tame. |

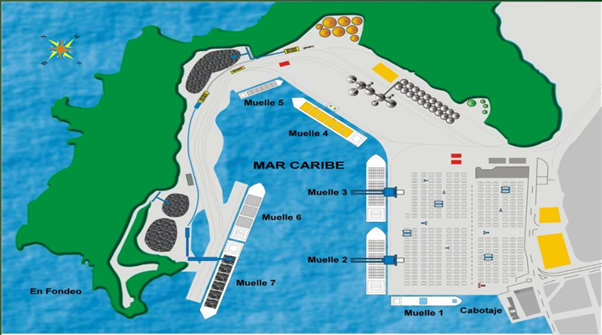

Port Picture

Layout of Cartagena Port

Description and Contacts of Key Companies

Companies inside the port are major contributors in the supply chain, most of them are private. Services provided: container handling, loading and unloading of vessels, pilots’ services, vehicles, customs agency, port operators, support catering vessels, safety and inspection of goods.

Note: Pilotage is compulsory for all ships of more than 200 tons. Pilotage is available on a 24-hour basis. The pilot will board the vessel one (1) mile from Sea Buoy. Distance from pilot station to the port is 9 miles.

4.4 Colombia Port and Waterways Company Contact List

Port Performance

Cartagena’s dedicated container terminals are equipped to meet international performance standards. The Port has a regulation for humanitarian aid, in the event of a national emergency declared, humanitarian cargo vessels will have priority in the terminal.

|

Seasonal Constraints |

||

|---|---|---|

|

Occurs |

Time Frame |

|

|

Rainy Season |

Yes |

August to November |

|

Major Import Campaigns |

No |

Increased volumes of consumer goods during October and November. |

|

Other Comments |

n/a |

|

Container Terminal SPRC, Manga

Homepage: https://www.puertocartagena.com/

Located at the north shore of the inner harbour, the SPRC terminal of Sociedad Portuaria Regional Cartagena is closest to the city centre. The main berth is used to handle containers, 2 finger jetties are used for cruise vessels and auxiliary vessels.

Satellite view of SPRC-Terminal at Manga

Satellite view of SPRC-Terminal at Manga

View of Terminal at Manga, Cartagena

Gantries and transtainer at SPRC-Terminal at Manga

The terminal is operated at international operational standards and are equipped to handle Post-Panamax vessels. Containers handled are mostly transshipment cargo with a local percentage of only 25% thus creating low gate throughput relatively to terminal activity. Shipping lines using the terminal to link Pacific and Atlantic trade include Hamburg Süd, Maersk, Hapag Lloyd, CMA-CGM and Cosco. Warehouse spaces are presently rented out or in use; large scale container stripping would likely have to take place outside the terminal.

|

Handling Figures for 2019 |

|

|---|---|

|

Vessel Calls |

1,187 |

|

Container Traffic (TEUs) |

845,938 TEUs |

|

Handling Figures Bulk and Break Bulk for 2019 |

|

|---|---|

|

Bulk (MT) |

- |

|

Break bulk (MT) |

1,446 |

Discharge Rates and Terminal Handling Charges

For information on port rates and charges, please see the following link: https://www.puertocartagena.com/en/cargo-services

Berthing Specifications

|

Type of Berth |

Quantity |

Length (m) |

Maximum Draft (m) |

Comments |

|---|---|---|---|---|

|

Conventional Berth |

4 |

4 x 190 m |

n/a |

According to operator |

|

Container Berth |

1 |

700 m |

15.50 m |

According to operator |

|

Silo Berth |

|

|||

|

Berthing Tugs |

|

|||

|

Water Barges |

|

General Cargo Handling Berths

|

Cargo Type |

Berth Identification |

|---|---|

|

Imports - Bagged Cargo |

|

|

Exports - Bagged Cargo |

|

|

Imports and Exports - RoRo |

|

|

Other Imports |

Port Handling Equipment

|

Equipment |

Available |

Total Quantity and Capacity Available |

Comments on Current Condition and Actual Usage |

|---|---|---|---|

|

Dockside Crane |

No |

- |

- |

|

Container Gantries (STS) |

Yes |

6 |

6 x 21 Rows outreach 20 x 20’ Twin lift Super Post Panamax 42 m underspreader to berth 65 MT under spreader 85 MT under hook |

|

Mobile Cranes |

Yes |

2 |

100 MT at 21 m outreach 23 MT at 50 m outreach |

|

Reachstacker |

Yes |

6 |

5 Full cntnr Reach Stacker 1 Mty cntnr Reach Stacker |

|

RoRo Tugmaster (with Trailer) |

Yes |

89 |

02 x 20’ carry |

|

Transtainer |

Yes |

28 |

6 + 1, single lift |

|

Forklifts |

Yes |

6 |

4 x 3 MT 1 x 7 MT 1 x 12 MT |

Container Facilities

|

Facilities |

20 ft and 40 ft |

|---|---|

|

Container Facilities Available |

Yes, International standards (15 hectares) |

|

Container Freight Station (CFS) |

Yes 10,692 m2 |

|

Refrigerated Container Stations |

One station, cold room, 3 platforms |

|

Yard Capacity Details (Slots 20’) |

28,500 TEUs |

|

Daily Take Off Capacity |

3,542 |

|

Number of Reefer Stations |

1,140 |

|

Emergency Take-off Capacity |

35 moves / hour / gantry |

|

Off take Capacity of Gang Shift |

1,771 |

The terminal is handling container and bulk cargo using mobile cranes and vessel’s gear.

Customs Guidance

DIAN is the main government customs agency in Colombia, when an import or export exceeds USD1000, importer / exporter should use a customs broker for this process. Customs regulations as per decree 2685 and Muisca regulations stipulate that:

- All cargo on board a vessel, with destination Colombia must be manifested.

- The manifest and bills of lading have to be registered to Customs systems - Muisca, 12 hours prior to ship's arrival.

- Cargo not covered by manifest may not be discharged. If discharged it will be immediately confiscated by Customs.

Customs may take 1-3 days maximum in the process, depending on the selectivity of inspection which goods was subjected. In Colombia the customs authorities are the most influential institution in the process of nationalization. Customs procedures can be affected by delays or technical problems by the DIAN system when making records, or documentary procedures unrealized by the importer / exporter. It is recommended to do load tracking every time and obey the instructions of the officials, as long as they are legal and fair.

DIAN have a special type of import procedure for emergencies, under this mode delivery to the end user may do without any prior processing.

For more information on customs in Colombia, please see the following links: https://www.dian.gov.co/andhttps://muisca.dian.gov.co/.

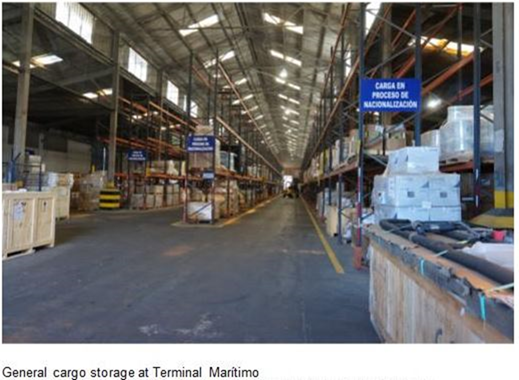

Terminal Information

Multipurpose Terminal

Cartagena Container Terminal Operator (www.ccto.com.co)

On the east coast of the inland port, the terminal of CCTO (Operador de Terminal de Contanedores de Cartagena S.A.S), a joint venture of COMPAS and APM TERMINALS is located on an artificial island. In 2016, APM Terminales, a world-renowned company in the port industry (member of the MAERSK group) and the Colombian-based port and terminal operator, Compañía de Puertos Asociados S.A. (Compas S.A.) formed Cartagena Container Terminal Operator (CCTO). The joint venture manages and operates the multipurpose terminal at the second busiest container port in Colombia.

With a planned investment of US $ 200 million, CCTO has three Ship-to-Shore cranes, increased the draft from 12 to 14.5 meters and has automated its operations for maximum efficiency. This allows the terminal to handle new Panamanian vessels of up to 13,000 TEU capacity, which can now transit through the Panama Canal after its lock expansion project completed in the summer of 2016.

CCTO institutional video: https://www.youtube.com/watch?v=d3OgWgKpEJ4

Satellite view of CCTO-Terminal at el Bosque

Mobile harbour cranes at berth of CCTO-Terminal

Warehouses and silos at CCTO-Terminal

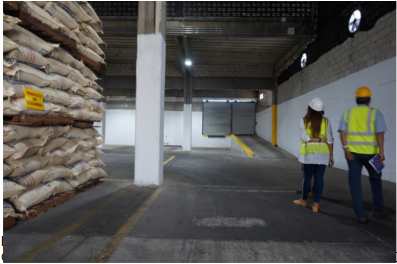

Big bag storage at warehouse of CCTO-Terminal

Grain and Bulk Handling

The terminal handles CONTAINER cargo, FRACTIONAL cargo, PROJECT cargo, BULKS, COKE and VEHICLES, using both: mobile cranes and ship equipment.

Main Storage Terminal

The CCTO – multipurpose terminal offers 65,000 tons silo capacity for grains and 7,000 m2 warehouse space.

|

Storage Type |

Number of Storage Facilities |

Area (m2) |

|---|---|---|

|

Bagged Cargo |

5 warehouses |

7.000 m2 warehouse space (plus 4.000 sqm adjacent to the terminal) |

|

Refrigerated Cargo |

n/a |

110 connection points for reefer containers |

|

General Cargo |

See “bagged cargo” |

See “bagged cargo” |

Other capabilities:

• Dock storage, filling and dewatering, and last mile delivery (estimated savings of up to US $ 150 per container)

• Efficient cargo dispatch process in 12 hours

• Optimized door process with truck turn time of 23 minutes

• Well-connected hinterland serving the automotive and petrochemical industry

Total area: 22 Hectares

Operating capacity: Handling 4 million tons / year

Annual container capacity: 250,000 TEU

Access lanes tracks: 5

Refrigerated Container Connections: 110

Berth length: 660m

Handling Equipment

Mobile harbor cranes: 4 (capacity of 100 tons each)

Reach Stacker: 5

Top Loaders: 5

Access channels

North Channel, with a maximum depth of 12 meters BW. and channel width 80 meters Canal Sur, with a maximum depth of 11.5 meters BW. and channel width of 100 meters.

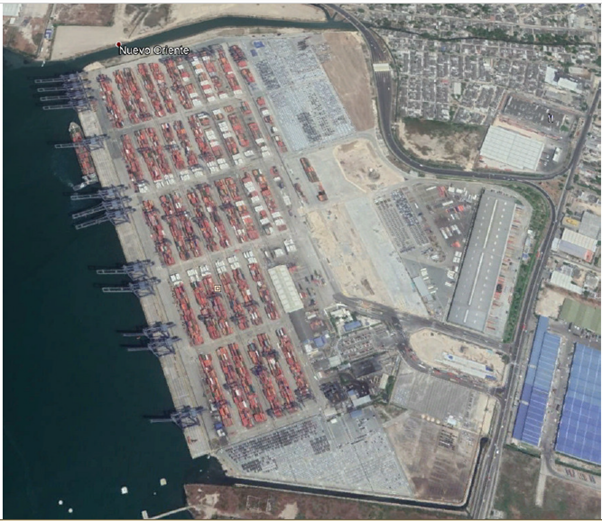

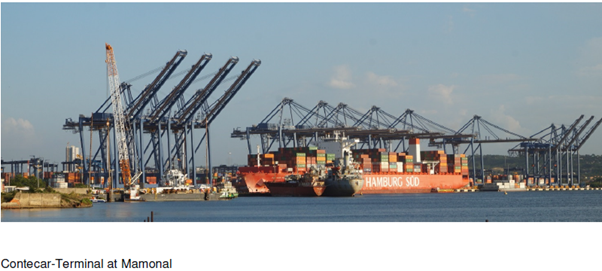

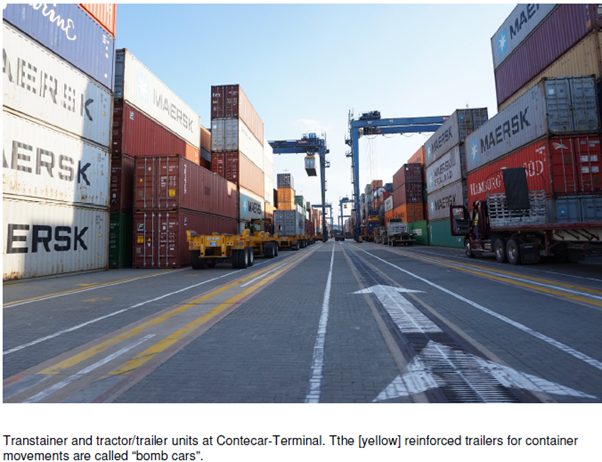

CONTAINER TERMINAL Contecar, Mamonal

Homepage: http://www.puertocartagena.com

https://www.puertocartagena.com/en/companies-withinorganization/contecar

Located in the north-east part of Cartagena Bay, the Contecar terminal (Terminal de Contenedores de Cartagena) of Sociedad Portuaria Regional Cartagena is handling container and RoRo cargo.

Satellite view of Contecar-Terminal at Mamonal

The terminal is operated at international operational standards and are equipped to handle Post- Panamax vessels. Containers handled are mostly transshipment cargo thus creating low gate through put relatively to terminal activity. Warehouse spaces are presently rented out or in use; large scale container stripping would likely have to take place outside the terminal.

Additional Information:

- CONTECAR It is prepared to receive the largest ships in the world.

- It has the capacity to mobilize 3.2 million TEUs per year.

- It functions as a connection center (hub) for shipping companies and as an International Logistics Distribution Center (CDLI) for multinationals.

- It has the latest technology infrastructure and equipment to offer high-quality services.

- It has infrastructure to mobilize self-rolling cargo (Ro-Ro) and is a specialist in car cargo for the national and regional market.

- Handles project loads: heavy or oversized parts (over gauge)

- It has connectivity to direct routes in global trade networks.

Discharge Rates and Terminal Handling Charges

https://www.puertocartagena.com/en/cargo-services

Berthing Specifications

|

Type of Berth |

Quantity |

Length (m) |

Maximum Draft (m) |

Comments |

|---|---|---|---|---|

|

Conventional Berth |

n/a |

|

||

|

Container Berth |

1 |

970 m |

16.50 m |

According to operator |

|

Silo Berth |

n/a |

|

||

|

Berthing Tugs |

n/a |

|

Container Handling Equipment

|

Equipment |

Available |

Total Quantity and Capacity Available |

Comments on Current Condition and Actual Usage |

|---|---|---|---|

|

Dockside Crane |

No |

- |

- |

|

Container Gantries (STS) |

Yes |

13 |

3 x 17 Rows Outreach 2 x 20’ Twin Lift Panamax 38 m under spreader to berth 65 MT under spreader 70 MT under hook 10 x 23 Rows outreach 2 x 20’ twin lift Panamax 45 m under spreader to berth 65 MT under spreader 80 MT under hook |

|

Mobile Cranes |

Yes |

2 |

100 MT at 21 m outreach 23 MT at 50 m outreach |

|

Reachstacker |

Yes |

12 |

10 Full cntnr Reach Stacker 2 Mty cntnr Reach Stacker |

|

RoRo Tugmaster (with Trailer) |

Yes |

143 |

02 x 20’ carry |

|

Grain Elevator with Bagging Machines |

No |

- |

- |

|

Transtainer |

Yes |

42 |

6 + 1 Single lift |

|

Forklifts |

Yes |

7 |

4 x 3 MT, 1 x 7 MT, 2 x 16 MT |

Container Facilities

|

Facilities |

20 ft and 40 ft |

|---|---|

|

Container Facilities Available |

Yes, International standards. 29 Ha |

|

Container Freight Station (CFS) |

Yes 50,673 m2 |

|

Refrigerated Container Stations |

1 station, cold room, 12 plattforms |

|

Yard Capacity Details (Slots 20’) |

45,000 TEUs |

|

Daily Take Off Capacity |

6,552 |

|

Number of Reefer Stations |

1,512 |

|

Emergency Take-off Capacity |

35 moves / hour / gantry |

|

Off take Capacity of Gang Shift |

3,400 |

Puerto Bahia, Barú Multi-purpose Terminal

Website: www.puertobahia.com.co

The multipurpose terminal Puerto Bahía was inaugurated on August 28, 2015, it is the youngest port in the region. Puerto Bahía, being a new terminal, has always seen a growth in its volumes, equipment and facilities. In 2018, after three years of its inauguration in the bay of Cartagena, the Puerto Bahía multimodal maritime terminal met the objective of covering the deficit in hydrocarbon export and storage capacity in Colombia and managed to mobilize 118 million barrels. Currently the hydrocarbons business mobilizes 85% of total revenues, 10% are vehicles and 5% project cargo (machinery and materials) and others. Added to these figures are accumulated exports of more than 128,000 tons and imports that exceed 195,000 tons in general cargo since 2015.

Puerto Bahía is located on the southern coast of Cartagena Bay and is adjacent to a liquid bulk terminal. Known today as the first mobile cargo terminal in the Caribbean, the port specialized in hydrocarbons will enable an additional 10 hectares to transport merchandise without the need for cranes.

Container storage yard at the Puerto Bahía terminal, Cartagena. Courtesy Puerto Bahía

Multipurpose Terminal

Puerto Bahía has a specific area for the transport of general cargo, specialized in handling extra-heavy, oversized and rolling cargo (Roll On - Roll Off), in addition to having a state-of-the-art logistics system.

In its first phase, this terminal includes a 300-meter dock and 27 hectares of storage yards. Once the Port is completed, this pier will increase its capacity by another 300 meters, thus completing 600 linear meters and 18 meters of natural draft along the pier line.

General Cargo Terminal

The general cargo terminal will supply a great need in Cartagena's port transport, handling loose cargo, which includes shipping with unique specifications and that generally do not adhere to container transport processes. Without a doubt, Puerto Bahía will become the first departure from Cartagena for this type of cargo, with a personalized service that adjusts to the needs of each customer and their shipments.

Ro-Ro Terminal

Puerto Bahía is the only port terminal specialized in Roro cargo in the Caribbean, providing its users with ample spaces for cargo storage (10,000 parking lots), value-added services and cargo handling facilities such as designated areas in the port for centers. of distribution.

Liquid Terminal

The Puerto Bahía Port Society houses the first fully automated bulk liquid handling dock in the country, which has the highest technology for loading and unloading of hydrocarbons and a direct transfer capacity to the dock of up to 1.2 million barrels per ship in less than 36 hours. The liquids terminal has two berthing positions, a depth of 22 meters, a dock for loading and unloading barges, and a station for dispatching and receiving cargo by land. In terms of liquid transportation, Puerto Bahía is the first terminal in Latin America with the capacity to receive Suezmax and Panamax type tankers.

In its first phase, there are eight storage tanks with a capacity of 333,000 barrels each. Once all expansions are completed (which includes a total of 12 additional tanks), the capacity will be increased to 3.33 million barrels. The storage and transportation of the liquids terminal will be managed by the Oiltanking company, one of the world's leading organizations in the storage of oil, chemicals, gases and dry bulk products, with more than 40 years of experience in the sector.

Puerto Bahía Liquid Terminal, Cartagena

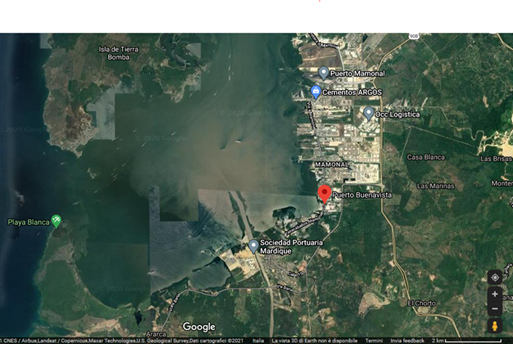

Puerto Buenavista Multi-Purpose Terminal

https://www.puertobuenavista.com/es/la-empresa

Puerto Buenavista S.A. was created in August 2009 with the need to improve efficiency in the import of raw materials for the company Yara Colombia S. A. in the city of Cartagena. In November 2012, and visualizing the opportunities to orient itself to new customers and markets, it was consolidated as a multipurpose terminal in the Mamonal industrial zone. Therefore, Compas and Saam join this company, who contribute their extensive experience in the development and management of port activities in Latin America.

Main Partners:

- Yara Colombia S. A.

- Compas S. A.

- Saam Puertos S. A.

Infrastructure

Number of docks - (1) -221m

Operating Draft - 10.2 m

Maximum Heel - 190 m

Maximum Beam - 32m

Max Airdraft -14m WLTHC

Hours of Operation -24 hours

Photo Puerto Buenavista- Cartagena

Satellite view of Terminal Puerto Buenavista, Cartagena

Hinterland Information

All port terminals of Cartagena are linked to the national road network. Traffic from and to Puerto Bahia does NOT have to traverse the city center.

Port Security

The Sociedad Portuaria Regional de Cartagena has a special security department to protect the integrity of the persons, goods and port operations, with all the policies established by: ISPS, Customs Trade Partnership against Terrorism and a Container Security Initiative.

|

Security |

|

|---|---|

|

ISPS Compliant |

Yes |

|

Current ISPS Level |

1 |

|

Police Boats |

Yes |

|

Fire Engines |

Yes |

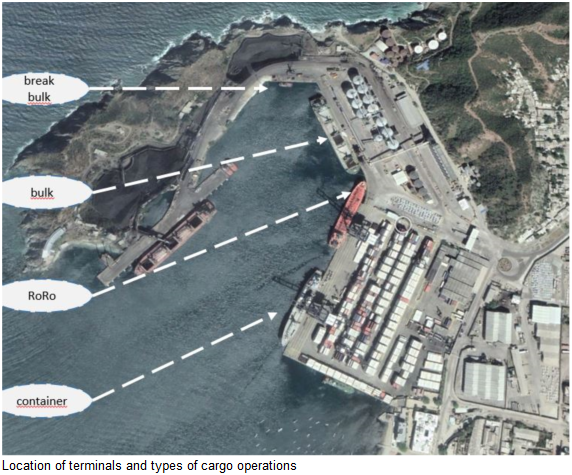

2.1.4 Colombia Port of Santa Marta

Port Overview

Located on the Caribbean Sea, the Port of Santa Marta is a major commercial port importing grain and general cargo and exporting coal, bagged coffee, containerized fruit, fuel oil and palm oil. Santa Marta moves the third largest cargo volume in Colombia. Its modern container terminal uses two Post-Panamax gantry cranes (STS) and transtainers (RTG). The terminal claims to be presently operating at 60 % of its capacity. 90 % of import containers are stripped in the port.

Automated bulk discharge into silos (600 – 800 mt/h) for one hatch. Additional or alternative discharge by grabs to trucks possible. An external operator is offering bagging operations at the jetty. The berthing preference of cruise vessels and perishables export might – in single instances - cause delays for container imports. The port is operated by Sociedad Portuaria Regional de Santa Marta S.A..

Port website: http://www.spsm.com.co/

Port of Santa Marta Institutional video: https://www.youtube.com/watch?v=wC7foJl-H3Y

Key port information may also be found at: http://www.maritime-database.com

|

Port Location and Contact |

|

|---|---|

|

Country |

Colombia |

|

Province or District |

Magdalena |

|

Nearest Town or City with Distance from Port |

Santa Marta (6 km) |

|

Port's Complete Name |

Puerto de Santa Marta Sociedad Portuaria |

|

Latitude |

11.250146 |

|

Longitude |

-74.213396 |

|

Managing Company or Port Authority |

Sociedad Portuaria de Santa Marta |

|

Management Contact Person |

Mauricio Suarez Ramirez |

|

Nearest Airport and Airlines with Frequent International Arrivals/Departures |

International Airport Simon Bolivar Avianca, Latam, solar Cargo, Aero Sucre, other Southamerican Region Airlines |

Port Picture

Sociedad Portuaria de Santa Marta

Description and Contacts of Key Companies

Companies inside the port are major contributors in the supply chain, most of them are private. Services provided: container handling, loading and unloading of vessels, pilots services, vehicles, customs agency, port operators, support catering vessels, safety and inspection of goods. Note: Pilot assistance compulsory for vessels going in/out of the port as well for shifting between piers. Pilot station/boarding position 0.5 nautical mile at the light: Morro Grande. Santa Marta port control station and pilots can be contacted on VHF channels 11, 16 and 74. A pilot ladder shall be rigged on the starboard side of each Vessel unless otherwise instructed.

Santa Marta International Terminal Company S.A. (SMITCO), is a company incorporated under a partnership between SSA International and Sociedad Portuaria de Santa Marta. It is constituted as a port operator; however, it is committed to managing, controlling and marketing the Container Terminal of the Port of Santa Marta. SMITCO has a wide portfolio of services for the handling of containerized cargo. The services provided are: Maritime operation, land operations, containers and container emptying, authorities inspection services, 24-hour sentry box service, areas for handling refrigerated cargo, connection and monitoring of refrigerated containers 24 hours, covered warehouse storage. for loose cargo handling, cargo traceability.

4.4 Colombia Port and Waterways Company Contact List

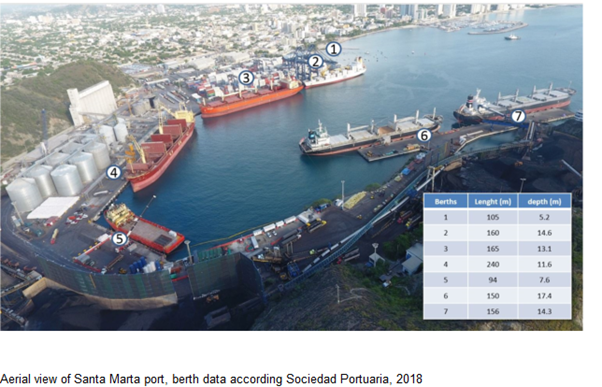

Port Performance

Port of Santa Marta Institutional video: https://www.youtube.com/watch?v=wC7foJl-H3Y

Port extension: 336,356 m2, port connected to hinterland by both road and rail. 7 berths of a total length of 1070 m. Due the last investment, the port increase the annual capacity of the container terminal, plus Santa Marta Port is the only one in the Atlantic Coast with rail service, offering the possibility of direct upload and download at docks, but to exploit this advantage, port is awaiting that government authorized the construction of a railway cargo variant of 17.5 km, which would allow the terminal to be connected with the centre of the country.

The Port has a regulation for humanitarian aid, in the event of a national emergency declared, humanitarian cargo vessels will have priority in the terminal.

|

Seasonal Constraints |

||

|---|---|---|

|

Occurs |

Time Frame |

|

|

Rainy Season |

Yes |

June to October |

|

Major Import Campaigns |

No |

The high season of commerce, is considered in the months of October and November, traders are preparing for Christmas. |

|

Other Comments |

n/a |

|

|

Handling Figures for 2017 |

|

|---|---|

|

Vessel Calls |

n/a |

|

Container Traffic (TEUs) |

208,000 TEUs |

|

Handling Figures Bulk and Break Bulk for 2018 |

|

|---|---|

|

Bulk (MT) |

n/a |

|

Break bulk (MT) |

n/a |

Discharge Rates and Terminal Handling Charges

http://www.spsm.com.co/SIPEN/Servicios/TarifasPuerto.aspx

Berthing Specifications

http://www.spsm.com.co/SIPEN/Puerto/Plano.aspx

|

Type of Berth |

Quantity |

Length (m) |

Maximum Draft (m) |

|---|---|---|---|

|

Conventional Berth |

1 |

94 m |

7.6 m |

|

Container Berth |

2 |

160 m; 165 m |

14.6; 13.1 m |

|

Silo Berth |

1 |

240 m |

11.6 m |

|

Berthing Tugs |

Yes |

||

|

Water Barges |

Yes |

General Cargo Handling Berths

|

Cargo Type |

Berth Identification |

|---|---|

|

Imports - Bagged Cargo |

1 to 6 |

|

Exports - Bagged Cargo |

1 to 6 |

|

Imports and Exports - RoRo |

2 to 6 |

|

Other Imports |

7 coal export |

Port Handling Equipment

A private company manages Santa Marta Port by a concession granted by the government. Santa Marta port offers an excellent infrastructure and logistic services for solid grain imports in the country.

|

Equipment |

Available |

Total Quantity and Capacity Available |

Comments on Current Condition and Actual Usage |

|---|---|---|---|

|

Dockside Crane |

Yes |

1 |

operational |

|

Container Gantries |

Yes |

2 |

Post-Panamax |

|

Mobile Cranes |

Yes |

1 (50 MT) |

n/a |

|

Reachstacker |

Yes |

4 (45 MT) + 3 |

4 Toploader and 3 Sideloader for empties |

|

RoRo Tugmaster (with Trailer) |

No |

33 / 20 |

33 tractors, 20 reinforced container trailers |

|

Grain Elevator with Bagging Machines |

Yes |

1 (400 to 600 to/hour). |

Suction equipment, bagging equipment available |

|

Transtainer |

Yes |

4 |

stacking 1 over 6 |

|

Forklifts |

Yes |

29 |

6 Electrical |

Container Facilities

Terminal Container is managed by Santa Marta International Terminal Company S.A., a cooperation between the port and SSA International.

PUERTO DE SANTA by tatianatrujillo1808

Sociedad Portuaria de Santa Marta

Sociedad Portuaria de Santa Marta

|

Facilities |

20 ft and 40 ft |

|---|---|

|

Container Facilities Available |

8.7 hectares for storage and operation. Container cleaning and repair available. Attend up to 300000 TEUs / year. Land transport, staffing and stripping of containers. |

|

Container Freight Station (CFS) |

Area service for inspection with 24 hours security, storage, and tracking cargo service. |

|

Refrigerated Container Stations |

Connections and tracking at storage zone. Transfer units to keep cold chain during inspection or cross docking. |

|

Other Capacity Details |

n/a |

|

Daily Take Off Capacity |

408 |

|

Number of Reefer Stations |

576 |

|

Emergency Take-off Capacity |

n/a |

|

Off take Capacity of Gang Shift |

n/a |

Sociedad Portuaria de Santa Marta

Customs Guidance

DIAN is the government customs agency in Colombia. If import or export value exceeds USD1,000, a custom’s agency should be employed. Customs regulations per decree 2685 and Muisca regulations stipulate that:

- All cargo on board a vessel, with destination Colombia must be manifested.

- The manifest and bills of lading have to be registered to Customs systems – Muisca, 12 hours prior ship's arrival.

- Cargo not covered by manifest may not be discharged. If discharged it will be immediately confiscated by Customs.

Customs may take 1-3 days maximum in the process, depending on the selectivity of inspection which goods was subjected. In Colombia the customs authorities is the most influential institution in the process of nationalization, Customs Procedures can be affected by delays or technical problems by the DIAN system when making records, or documentary procedures unrealized by the importer / exporter. It is recommended to do load tracking every time and obey the instructions of the officials, as long as they are legal and fair.

DIAN have a special type of import procedure for emergencies, under this mode delivery to the end user may be affected without any prior processing.

Import and export procedures: http://www.spsm.com.co/Servicios/Procedimientos.aspx

For more information on customs in Colombia, please see the following link: https://www.dian.gov.co/

Terminal Information

Multipurpose Terminal

General cargo terminal operated by Sociedad Portuaria’s affiliate Operlog. Operations by MHC (mobile crane) and vessel’s gear.

Grain and Bulk Handling

Sociedad Portuaria/Operlog and Almagrario are the main port operatorsfor bulk cargo. About 100,000 tons can be stored in warehouses and silos within the port, additional 50,000 in the vicinity. The automated suction grain elevator has a capacity of 400 to 600 tons/h and is connected to the port’s silos. Additionally 4 shutes (45 m³), 6 grabs, excavators and trucks are available for operations with vessel’s gear.

Bagging equipment can be rented locally.

Main Storage Terminal

|

Storage Type |

Number of Storage Facilities |

Area (m2) |

|---|---|---|

|

Bagged Cargo |

Warehouse |

Existing warehouses behind berth 2 and 3 were dismantled for the container yard. No information was supplied regarding which percentage of the approx. 90,000 sqm warehouse space for bulk cargo would be also available for break bulk. |

|

Refrigerated Cargo |

n/a |

At SMITCO terminal containers. |

|

General Cargo |

n/a |

n/a |

Stevedoring

Private, Main Port operators: Coremar S.A.S.; Estinorte; Intertug S.A.; Operlog and Almagrario, handling the main cargo types: Bulk, container, general cargo. They offer modular storage, all certified under ISO 9001-2000, and provide equipment and a range of services.

Hinterland Information

Among the advantages offered by the capital of Magdalena, its geographical location stands out. It is the Caribbean city closest to the center of the country compared to cities like Barranquilla and Cartagena, which is why its land freight is cheaper and more competitive compared to other terminals in the Colombian Caribbean. It is also the only port on the Atlantic coast with a railway, which is why it is able to offer loading and unloading services directly at the docks.

Close to the port operates the free trade Tayrona Zone.

Port Security

Santa Marta port have a security regulation for personal protection, industrial and environmental activities. They have an emergency plan that divide the port in 7 zones. The port has a special security lounge with the last generation in security equipment’s, long distances cameras with night vision and infrared detection as well as modern communication equipment.

|

ISPS Compliant |

Yes |

|---|---|

|

Current ISPS Level |

Level 1 |

|

Police Boats |

Yes |

|

Fire Engines |

Yes |